Description

1. Product Introduction

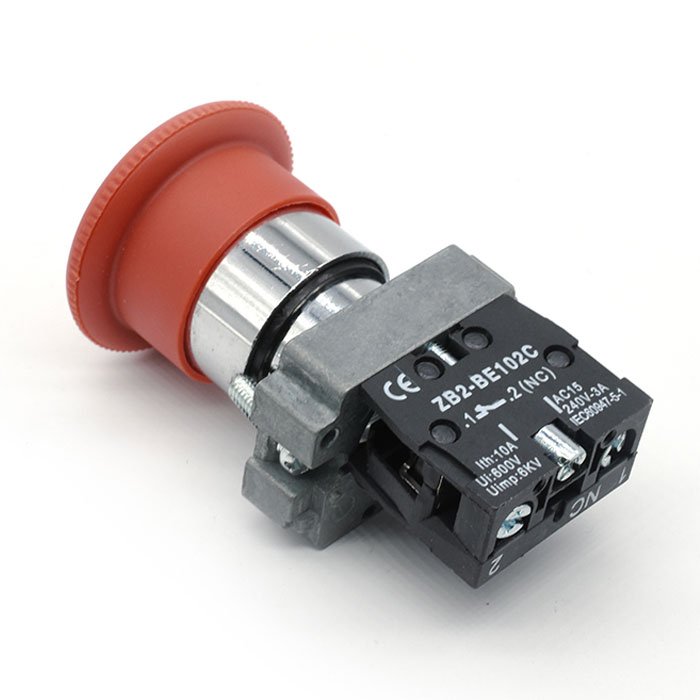

The plastic emergency push buttonis equipped with a series of strong but economical plastic guide rails. The strong and durable equipment is suitable for Industry and outdoor. These emergency stop switches are made of glass fiber reinforced thermoplastic and can directly replace the existing 22mm metal guide rails.

2.Product Parameter (Specification)

| Rated insulation voltage | AC 600V (50/60Hz) | |

| Convectional current | 10A | |

| Insulation resistance | ≥50MΩ | |

| Contact resistance | ≤25MinΩ | |

| Mechanical life | 100*104(Pushbutton) | 50*104(Selector switch/Key switches) |

| Electrical life | 500*104(Pushbutton) | 250*104(Selector switch/Key switches) |

1.Surrounding temperature : -25℃~+55℃;

2.Air relative humidity : ≤85%;

3.It can be normally work under following condition : Vibration frequency is 2-80Hz and acceleration speed is 0.7g/h;

4.Pollution grade III,installation sort is III, protection grade is up to IP65;

5.Altitude : ≤2000m.

3.Product features and applications

The advantage of the button is the instantaneous switch function of the button: press to open, release and close. The plastic emergency push button has the advantages of safety, long service life, high reliability, excellent design, color, design and function coordination. The color coding of the contact block is easy to identify: green indicates normally open and red indicates normally closed

4. Product Details

plastic emergency push button are protected to IP65

Self-cleaning gold-plated silver contacts provide reliable, low-energy switching

Contacts rated at 10 amps thermal current A300

Pressure plate wiring terminals for easy, secure wiring, accepting up to 14 AWG wire

Contact blocks are color coded for easy identification: green for normally open, red for normally closed

It can be completed with one hand without any special tools. Slotted holes are sufficient as mounting holes because complete distortion prevention has been integrated.